Sourcing of materials

GRI 2–6

Supply chain

Switzerland is a country with few natural resources and high production costs. Nevertheless, Swatch Group manages to carry out most of the value creation within the company and within Switzerland. In the few cases where this is not possible, the Group has strict selection criteria to ensure the avoidance or minimization of adverse environmental and social impacts in the supply chain.

Responsibilities in the company are clearly defined. Swatch Group has appointed a sustainability specialist with direct access to management for each company worldwide. The specialists have been trained to recognize potential risks. Swatch Group has also set up and continuously expanded its own office for sustainability with a focus on human rights in Asia.

Compliance with internal directives and with codes of conduct in the sourcing process has been independently audited. The Code is based on internationally recognized human rights and on the United Nations Guiding Principles on Business and Human Rights (UNGPs).

In the reporting period, a thorough risk analysis of sourcing and independent inspections of direct suppliers in high-risk countries were conducted.

Supplier Code of Conduct (SCoC)

The Supplier Code of Conduct applies to Swatch Group and its subsidiaries, as well as to suppliers and sub-suppliers of Swatch Group and its subsidiaries that supply products or services to Swatch Group companies.

The code is based on principles that are recognized in the industry and internationally, such as the United Nations Universal Declaration of Human Rights, the United Nations Guiding Principles on Business and Human Rights (UNGPs), the international labor standards of the International Labor Organization (ILO), the ILO’s code of practice for safety and health, the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, the 2019 Code of Practices of the Responsible Jewellery Council (RJC), the RJC’s 2017 Chain of Custody standard, the Social Accountability International SA 8000 standard, the OHSAS 18001 standard and anti-bribery guidance (ISO 37001).

The SCoC is periodically updated to take account of changes in legislation, regulations and Swatch Group guidelines.

↗ For more information about auditing suppliers, please see the "Supplier Audits" chapter, pages 103 / 104 of the Sustainability Report.

GRI 308-1, 308–2, 414–1, 414–2

Supplier Audits

Swatch Group FEPS (Far East Procurement Services) continuously verifies that direct suppliers and their facilities adhere to the Swatch Group Supplier Code of Conduct and applicable laws and regulations. All production facilities of direct suppliers and designated tier-2 suppliers are required to undergo two independent audits: responsible sourcing (RS audit) audit focus on assessing performance of labor and human rights, health and safety, environmental protection, and business ethics; quality assurance (QA audit) audit focus on verifying quality management system and facilities’ quality assurance processes.

FEPS determines which supplier facilities are audited in the relevant financial year, appoints independent third-party auditing firms to conduct the audits in compliance with our requirements, subsequently analyses the audit reports, and supports improvements in supplier facilities. All supplier facilities are audited regularly, at least once every two years. New supplier facilities cannot join the supply chain until they have been audited and qualified.

Swatch Group measures the performance of supplier facilities based on audit results through our internal rating system. Supplier facilities would be assigned one of the ratings listed in the below table. The rating system determines the supplier approval status and the period for which the approval is valid as well as the next planned audit.

Supplier facilities must be rated as A or B to be considered qualified. Should a supplier facility be rated C, a six-month period is provided to implement the necessary corrective measures and qualify for a follow-up audit. For supplier facilities that have received a D rating, there will be no collaboration if they are new facilities. For existing facilities, a three-month period is granted to implement the necessary corrective measures and qualify for a follow-up audit. If a supplier facility demonstrates no intention to remediate after our engagement, we terminate our relationship and cease future orders.

GRI 301-1

Minerals and metals from conflict-affected areas

With regard to minerals and metals from conflict-affected and high-risk areas, the imported and processed amounts of the materials defined by the Swiss Ordinance on Due Diligence and Transparency in relation to Minerals and Metals from Conflict-Affected Areas and Child Labor (DDTrO)1 have been recorded and analyzed. Swatch Group does not source many of these specified minerals and metals, and only in small quantities where it does. The threshold is only exceeded in the case of tungsten and gold. However, a traceability and documentation process is implemented to demonstrate that these materials do not come from conflict-affected or high-risk areas.

- Gold is sourced in its raw state according to the tariff number 7108. We source traceable gold from official and certified industrial mines in the US, Canada or Australia. All of the gold sourced in 2024 under tariff number 7108 comes from Australian mines. Carbon footprint was also taken into account when selecting mines.

- The tungsten used is sourced in powder form (tariff number 8101 10 00) via European suppliers and is produced from fully recycled base material.

Alongside Swiss legislation (DDTrO 2 and Art. 964 CO 3), the following international guidelines and standards were used as a basis:

- OECD Due Diligence Guidance for Responsible Business Conduct.

- OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas.

- Practical actions for companies to identify and address the worst forms of child labor in mineral supply chains.

GRI 408-1

Child Labor

Swatch Group has a zero-tolerance policy when it comes to child labor.

Policies and management system

Swatch Group has a zero-tolerance policy regarding human rights violations. This implicitly includes

child labor.

From the Swatch Group Code of Conduct, paragraph 14: “Swatch Group has zero tolerance for the use of child labor or labor involving minors who are under the age of 15 or the applicable statutory minimum employment age (whichever is higher). Suppliers are obliged to comply with International Labour Organization (ILO) standards and the applicable legal regulations.”

The Swatch Group Code of Conduct is based on internationally recognized human rights, such as those in the United Nations International Bill of Human Rights and the International Labour Organization’s Declaration on Fundamental Principles and Rights at Work. Our approach is based on the United Nations Guiding Principles for Business and Human Rights (UNGPs). In line with the UNGPs, we follow the higher standard whenever national law and international human rights standards differ. In addition, we follow the stricter standard whenever national legislation differs from the Group’s high environmental and health and safety standards. Where national law and Swatch Group’s high standards conflict, we respect national law while striving for the higher standard.

↗ For more information on "Child Labor" see pages 101 to 103 of the Sustainability Report.

GRI 204–1

Local suppliers

“Go Switzerland” was one motto of the founder of Swatch Group. Nicolas G. Hayek was always committed to Swissness throughout the Swiss watch industry and pursued the goal of being 100% Swiss Made from the launch of the Swatch brand in 1983.

This dedicated commitment to a production site in Switzerland and local sourcing has an enormous positive impact on managing the sustainable supply network. Swatch Group has no reason to change this – today or in the distant future. For watches, the percentage of local value creation, based on the applicable regulation on Swissness, is between 60% and 100%.

↗ For more information, see chapter "Recovery and preservation of arts and artisanship" on p. 91 of the Sustainability Report.

Basic supplier network management

In addition to the commitment to Swissness, strict selection criteria and the prioritization of reaction time, suppliers must also fulfill the internal guidelines of Swatch Group Quality Management and any ecological and legal regulations, and ensure legal compliance in terms of products, particularly REACH (Regulation on Registration, Evaluation, Authorization and Restriction of Chemicals), RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment).

↗ For more information on "Customer Service" see page 71 of the Sustainability Report.

GRI 302-2

Precious Metal Sourcing

Swatch Group uses different precious metals, primarily gold, silver, palladium and platinum, with gold accounting for the largest proportion by far. Primary gold is sourced exclusively from official and certified industrial mines in the US, Canada and Australia.

A low amount of gold is also purchased as components from suppliers. For further details see the “Gold in purchased components” section.

In addition, the Group has an in-house closed-loop gold processing system with a Group-owned foundry to reuse production residues internally. A relatively small part of the gold used is refined by certified Swiss gold foundries.

Recycled gold from external sources is avoided as traceability back to the mine is not achievable. Full traceability can be achieved with the Swatch Group sourcing strategy, which involves direct delivery from the mine to the refinery and on to the Group’s own gold processing facility, as well as the use of gold from internal processes.

A detailed review of the supply chain was carried out once again for the 2024 financial year, based on the Swiss Ordinance on Due Diligence and Transparency in relation to Minerals and Metals from Conflict-Affected Areas and Child Labor.

↗ For further details, see chapter “Minerals and metals from conflict-affected areas” on p. 100 of the Sustainability Report.

Primary gold

Traceable primary gold is sourced exclusively from official and certified industrial mines in the US, Canada and Australia, where the highest legal standards apply and where the mines are operated under extremely strict conditions set by the authorities and regularly monitored by them. The supply chain is kept as short as possible, through direct delivery from the mine to the refinery and then on to the in-house gold processing by Swatch Group. Sourcing gold from other regions and / or small-scale and artisanal mines where lower standards apply or where there are residual risks that non-traceable gold could enter the supply chain is not an option for Swatch Group. This clear and simple sourcing policy has proved to be very effective.

Countries of origin for primary gold in the year under review

| October 1–September 30 | 20241) | 2023 | 2022 |

| Australia | 100% | 100% | 100% |

| US | 0% | 0% | 0% |

| Canada | 0% | 0% | 0% |

1) Assurance conducted by PwC

|

Analyzing gold originsTraceability of raw materials and precious metals and the possibility of detecting any manipulations are key to validating the origins of gold. Since 2013, Swatch Group’s most important primary gold supplier has been using a method that enables impurities in the obtained mined gold to be analyzed on the basis of 15 elements and their interactions. This method allows the concentrations of the individual elements to be recorded and over the years a database has been established. Therefinery in Switzerland carries out an

|

This method enables the origins of gold to be tested, since some chemical elements are only present in certain regions while others are always present. By this analysis, raw materials from various regions can be identified. Each delivery of mined gold that will be used to produce primary fine gold for Swatch Group is analyzed to verify whether the country of origin is the US, Canada or Australia. No irregularities have been observed to date. |

Gold in purchased components

Wherever possible, suppliers of components use semi-finished products sourced from Swatch Group. If this is not possible, the supplier is required to

be RJC-certified.

In the year under review, 99.7% of the gold used was sourced in accordance with Swatch Group’s strict requirements. The remaining 0.3% was primarily sourced from Swiss and some European and Japanese suppliers that are not RJC-certified (with Japanese suppliers used for electronic systems only). The aim is to ensure that, in the future, this remaining proportion will also be sourced in accordance with Group’s strict guidelines.

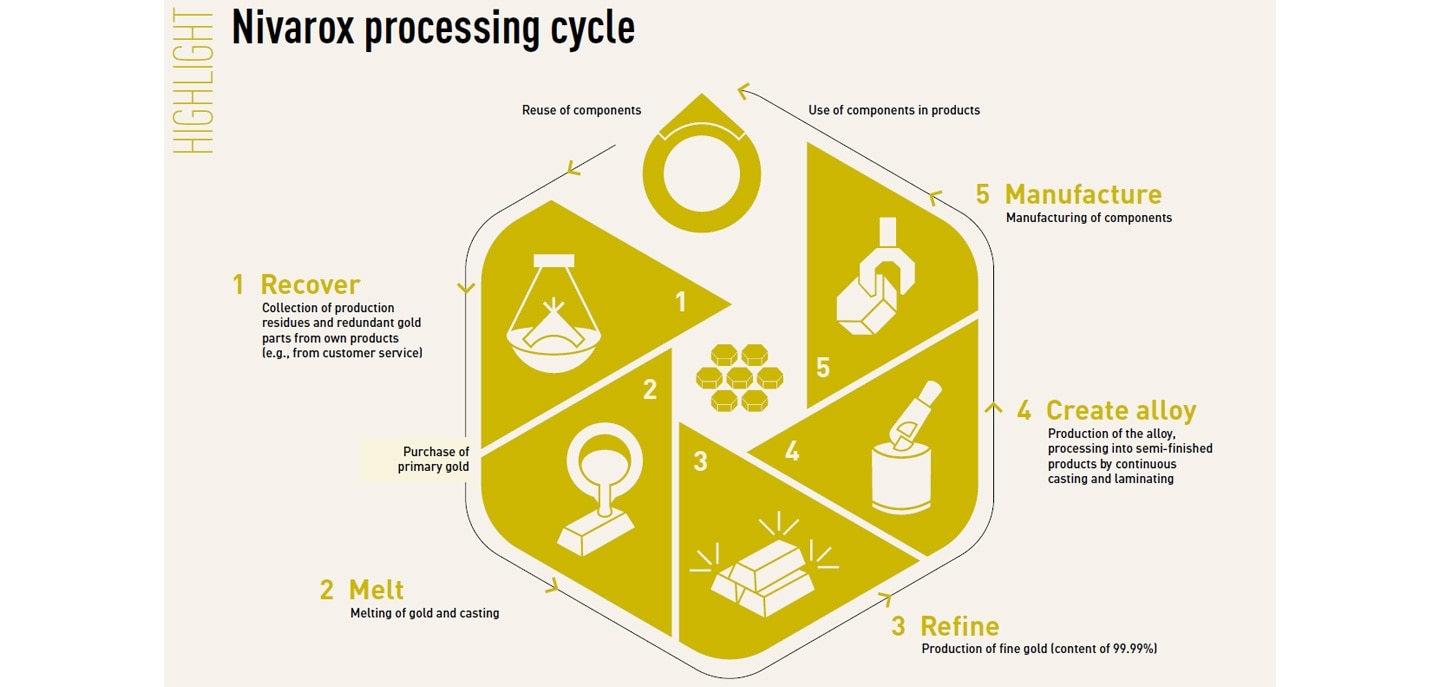

Swatch Group gold processing

The investments made in recent years in the Group’s foundry and refining facilities have fully internalized gold processing. After their manufacture, alloys are turned into semi-finished products or finished components, and production residues from these processes are reused internally. Swatch Group thus controls the entire gold processing chain through internal and clearly defined processes.

Nivarox-FAR plays a key role in this respect, as it processes Swatch Group’s gold production stocks in a closed and controlled cycle. Production residues can therefore be reused in the Group’s own foundry. Nivarox-FAR has the necessary federal authorization both as a foundry and as a commercial assayer (sworn assayer) and is certified according to the Responsible Jewellery Council Code of Practice and Chain of Custody (RJC CoP and CoC).

A small portion of gold chips and scrap is refined by a few external processors, depending on internal capacity.

To this end, Swatch Group only works with selected, established, long-term foundries that can demonstrate not only legal compliance according to all the provisions of the financial market supervisory authority, but also certified membership in the Responsible Jewellery Council (RJC) and / or the London Bullion Market Association (LBMA), and can guarantee through recognized certification that the precious metals delivered originate from ethically sound sources and conflict-free regions.

LIMITED ASSURANCE REPORT ON SELECTED SOURCING DISCLOSURES

Based on the work we performed, nothing has come to our attention that causes us to believe that selected indicators in the Sustainability Report 2024 of The Swatch Group AG, marked with the check mark , for the period ending 31 December 2024 are not prepared, in all material respects, in accordance with the suitable Criteria. (PricewaterhouseCoopers AG)