Liquidmetal®

Liquidmetal®: seamless bonding, remarkable hardness

The Liquidmetal® alloy is an amorphous metal – a metallic material with a disordered, non-crystalline atomic structure. Its fusion temperature is half that of conventional titanium alloys but when it is cooled, its hardness is three times as great as that of stainless steel. Its amorphous structure allows it to bond seamlessly with the ceramic bezel.

The Liquidmetal® is a bulk metallic glass alloy consisting of five elements: zirconium, titanium, copper, nickel and beryllium. A bulk metallic glass can, by virtue of its low critical cooling rate, be formed into a structure with a thickness of more than a tenth of a millimetre. Zirconium is an important constituent part both of the Liquidmetal® alloy and of the ceramic material which is made of zirconium dioxide (ZrO2).

Redefining longevity in the watch industry

The union of ceramics and Liquidmetal® at Omega

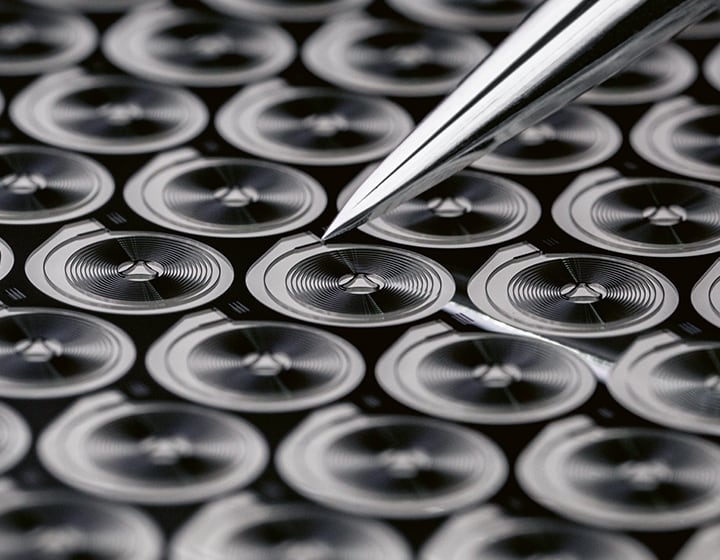

Liquidmetal® is used by Omega for the Seamaster Planet Ocean Liquidmetal® Limited Edition. The final, perfectly smooth bezel is particularly resistant to scratching and corrosion because of the hardness of the two components. First, ceramic rings are formed. The numbers and the fine lines of the minute scaling are then engraved into these ceramic bezel rings and polished. The alloy is heated and pressed into the cavities in the ceramic material after which any excess Liquidmetal® is removed. The Liquidmetal® can be manipulated at a lower temperature than metals normally used in watchmaking so the heating process does not damage the ceramic material.

The Liquidmetal® numbers and scales are then satin brushed. Because the ceramic is a harder material than the alloy, the satin brushing of the fine details can be done without affecting the ceramic bezel. The numbers and scaling then appear in bold, vivid contrast to the glossy ceramic background.

The Omega Seamaster Planet Ocean Liquidmetal® Limited Edition, which has a stainless steel case and bracelet, is driven by Omega’s revolutionary Co-Axial calibre 2500. These movements, which have been heralded for their long-term chronometric performance, are perfectly complemented by the ceramic and Liquidmetal® alloy components which are incredibly resistant to corrosion and scratching. The result is pure Omega: a design premiere which will retain its appearance indefinitely, blended with innovative Co-Axial technology.

Related news

Proposed appointment of Andreas Rickenbacher to the Board of Directors

Swatch Group will propose the appointment of Mr. Andreas Rickenbacher as a new member of its Board of Directors at the next Annual General Meeting, which takes place on May 12, 2026. This proposal is in line with the Group's desire to strengthen its governance and benefit from additional expertise within its Board of Directors. Andreas…

Key Figures 2025

Net sales of CHF 6 280 million, -1.3% at constant exchange rates compared to the previous year (-5.9% at current rates)1). Negative currency impacts of CHF 308 million. Excellent performance in the second half of the year with sales growth of 4.7% at constant exchange rates. Strong acceleration in the fourth quarter with sales up 7.2% worldwide…

Omega Seamaster Planet Ocean

OMEGA launches the 4th generation of the Planet Ocean. This complete redesign of the collection introduces seven new watches, including three different watch heads, with multiple options regarding bracelets or straps. Exactly 20 years after the first Planet Ocean was released, OMEGA’s watchmakers have returned to this emblematic collection,…